3D printing has come a long way from being a hobbyist’s tool to becoming a key driver of innovation across industries. Whether you are printing a prototype, functional part, or end-use product, the choice of filament material plays a crucial role in the final output. With so many options—PLA, ABS, PETG, Nylon, TPU, and even specialty blends—the big question is: How do you choose the best 3D filament for your project?

In this blog, we’ll break down the different types of 3D filaments, explore their strengths and limitations, look at their industry-specific applications, and provide practical tips to help you select the right material. Finally, we’ll explain how DigiGlen, a leading 3D printing service provider in Delhi/NCR, can guide you in making the right filament choice for your industry needs.

🔹 Why Choosing the Right Filament Matters

Not all filaments are created equal. The right filament can make your prototype durable, heat-resistant, flexible, or cost-effective, depending on the purpose. The wrong choice can lead to brittle prints, poor finishes, or wasted production costs.

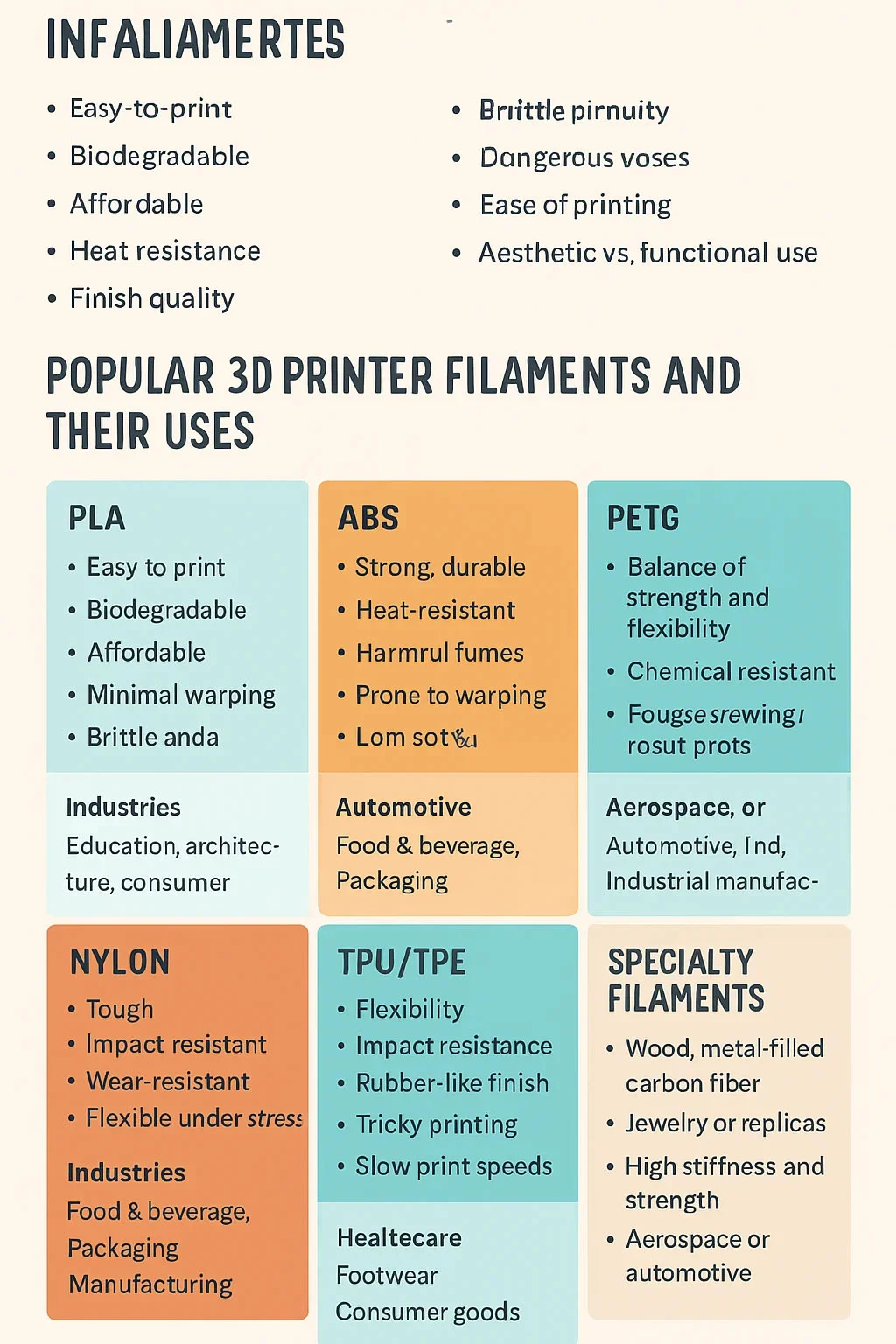

The filament impacts:

Strength & Durability – Can it withstand mechanical stress?

Flexibility – Is the part rigid or bendable?

Heat Resistance – Can it survive high temperatures?

Finish Quality – Does it look smooth and professional?

Cost Efficiency – Is it affordable for prototyping or batch production?

🔹 Popular 3D Printer Filaments and Their Uses

1. PLA (Polylactic Acid)

Pros: Easy to print, biodegradable, affordable, minimal warping.

Cons: Brittle, low heat resistance.

Best For: Prototypes, educational models, toys, architectural mockups.

Industries: Education, Architecture, Consumer Goods.

2. ABS (Acrylonitrile Butadiene Styrene)

Pros: Strong, durable, heat-resistant, widely used in automotive.

Cons: Emits fumes, prone to warping without heated bed.

Best For: Functional prototypes, durable enclosures, automotive parts.

Industries: Automotive, Consumer Electronics, Industrial Design.

3. PETG (Polyethylene Terephthalate Glycol)

Pros: Balance of strength and flexibility, chemical resistant, food-safe.

Cons: Stringing issues, requires careful temperature tuning.

Best For: Food containers, mechanical parts, outdoor products.

Industries: Food & Beverage, Packaging, Manufacturing.

4. Nylon (Polyamide)

Pros: Tough, impact-resistant, wear-resistant, flexible under stress.

Cons: Hygroscopic (absorbs moisture), requires controlled environment.

Best For: Engineering parts, gears, hinges, industrial tools.

Industries: Aerospace, Automotive, Industrial Manufacturing.

5. TPU/TPE (Thermoplastic Polyurethane/Elastomer)

Pros: Flexible, impact-resistant, rubber-like finish.

Cons: Tricky to print, slow print speeds needed.

Best For: Footwear soles, medical devices, wearables.

Industries: Healthcare, Footwear, Consumer Goods, Robotics.

6. Specialty Filaments (Wood, Metal-Filled, Carbon Fiber)

Wood Filaments: Aesthetic, used for models or décor.

Metal-Filled: Adds weight and metallic look, great for jewelry or replicas.

Carbon Fiber Reinforced: High stiffness and strength, ideal for aerospace or automotive.

🔹 How to Choose the Best Filament for Your Project

Choosing the right filament depends on a mix of technical needs, budget, and industry application. Below are some factors to consider:

✅ 1. Mechanical Requirements

Need strength? → Choose ABS, Nylon, or Carbon Fiber blends.

Need flexibility? → TPU or Nylon.

Need lightweight but durable? → PETG.

✅ 2. Heat & Chemical Resistance

For high-temperature environments (e.g., automotive engine parts), go with ABS, Nylon, or specialty filaments like PEI/PEEK.

For chemical resistance, PETG and Nylon are reliable.

✅ 3. Ease of Printing

For beginners, PLA is the safest and easiest to handle.

Advanced users with enclosed printers can go for ABS, Nylon, or TPU.

✅ 4. Aesthetic vs. Functional Use

If the part is visual/prototype only → PLA or Wood Filament.

If the part must be functional → ABS, PETG, Nylon, or TPU.

✅ 5. Budget Considerations

PLA and ABS are cost-effective.

Specialty filaments like Carbon Fiber or PEEK are premium and used mainly in aerospace or medical fields.

✅ 6. Industry-Specific Needs

Automotive → ABS, Nylon, Carbon Fiber.

Healthcare → TPU (flexible, biocompatible), PLA (prototyping).

Architecture → PLA, Wood Filament.

Manufacturing → PETG, Nylon.

Consumer Goods → TPU, PLA.

🔹 Pro Tips for Working with 3D Filaments

Store properly → Many filaments (especially Nylon) absorb moisture; keep them in airtight containers with silica gel.

Experiment with settings → Temperature, speed, and bed adhesion vary by filament.

Use the right printer setup → Heated beds, enclosures, or direct-drive extruders may be needed.

Combine materials smartly → For example, use PLA for outer shells and TPU for flexible joints.

🔹 DigiGlen: Your Partner in Filament Selection & 3D Printing

At DigiGlen, we understand that choosing the right filament is often the hardest step for businesses. With over 15 years of expertise in 3D modeling and 10+ years in 3D printing, we help clients not only print models but also select the most suitable filament based on industry requirements.

Automotive companies trust us for ABS, Nylon, and Carbon Fiber prints that withstand heat and stress.

Healthcare providers rely on us for biocompatible TPU and PLA prototypes for medical models and devices.

Architects partner with us for PLA and wood-filled filaments to create lifelike architectural mockups.

Manufacturers and product designers work with us to develop PETG and Nylon parts that are durable and production-ready.

With DigiGlen as your 3D printing partner, you don’t just get prints — you get expert guidance that ensures your material choice matches your vision, function, and budget.

🔹 Conclusion

The best 3D filament depends on your project’s function, industry, and performance requirements. From the ease-of-use of PLA to the industrial-grade durability of Nylon and Carbon Fiber, each filament brings unique benefits. By understanding their properties and applications, you can make smarter decisions, save costs, and achieve professional-quality results.

At DigiGlen, our mission is to help businesses and creators bridge the gap between concept and creation. Whether you’re developing a prototype, a medical device, or an industrial component, our team ensures you get the right filament for the right purpose.

👉 Ready to choose the perfect filament for your project? Contact DigiGlen today and let us guide you toward precision, durability, and innovation in every print.

Recent Comments

Post Widget

How to Choose the Best 3D Printing Filament: A Complete Guide

What is Layer Height in 3D Printing?

Mastering 3D Print Post-Production

Social Media Widget

Customer service

It’s not actually free we just price it into the products.

Fast Free Shipping

Get free shipping on orders of $150 or more

(within the US)

Returns & Exchanges

We offer free returns and exchanges within 30 days of purchase.

Secure payment

Your payment information is processed securely and encrypted.